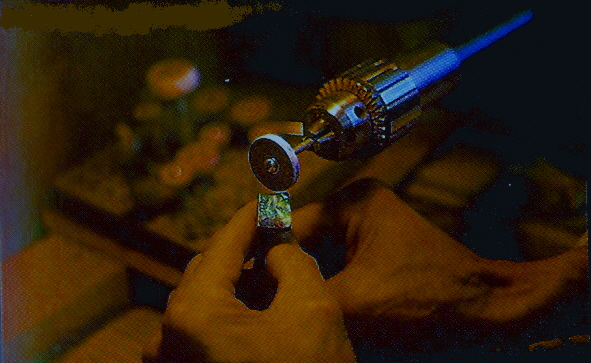

The Lapidary Process:

A Step by Step Guide to Cutting Queensland Boulder Opal

Cutting: Pleasure, Value Adding or Profession ?

|

Opal cutting is a specialised job but many miners do cut their own. Others prefer to leave it up to the cutter, wholesaler or manfacturer to decide the shape and cut appropriate for making jewellery.

|

|

The first lapidaries on the Australian Opal fields at the turn of the century rigged up sewing machines, bicycles etc. creating hand or foot operated contraptions with which to cut and polish Opals.

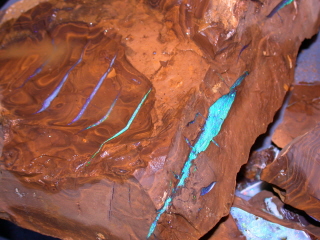

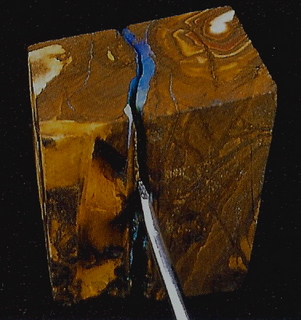

Some miners prefer to sell completely rough material just as they find it, others choose to block and face, or ‘rub’ it to reduce the element of hidden surprise. |

|

There has always been a strong demand for cutters services on the opal fields, particularly in Lightning Ridge where most of the Opals found are sold as cut and polished gems by their finders. There a single stone may provide enough money on which to retire.

|

|

Peter Christianos’ Hong Kong Opal cutting factory 1963. Photo Courtesy of www.opaline.com.au

|

|